Stainless steel wire is suitable for chromium content greater than 10.50%, the nickel content of less than 50% of the heat-resistant corrosion-resistant steel or welded steel. Using stainless steel wire determines by the material, the working conditions (including temperature and contact medium) to choose. There are several factors to consider when choosing stainless steel welding wire:

Corrosion resistance: Choose a grade of stainless steel that is suitable for the intended application and environment. For example, if the wire will be used to weld parts that will be exposed to saltwater, choose a grade with high corrosion resistance, such as 316 or 317 stainless steel.

Strength: Consider the strength requirements of the welded joint. For example, if the parts being welded will be subjected to high loads, choose a grade with high tensile strength, such as 302 or 304 stainless steel.

Non-magnetic properties: If the wire will be used in electronic or computer applications, choose a grade that is non-magnetic, such as 304L or 316L stainless steel.

Melting point: Consider the melting point of the stainless steel grade. For high-temperature applications, choose a grade with a high melting point, such as 309 or 310 stainless steel.

Cost: Consider the cost of the different grades of stainless steel welding wire. In general, higher grades of stainless steel will be more expensive than lower grades.

Availability: Make sure that the chosen grade of stainless steel welding wire is readily available from suppliers.

Weldability: Consider the weldability of the stainless steel grade. Some grades, such as 302 and 304, are more weldable than others, making them easier to work with.

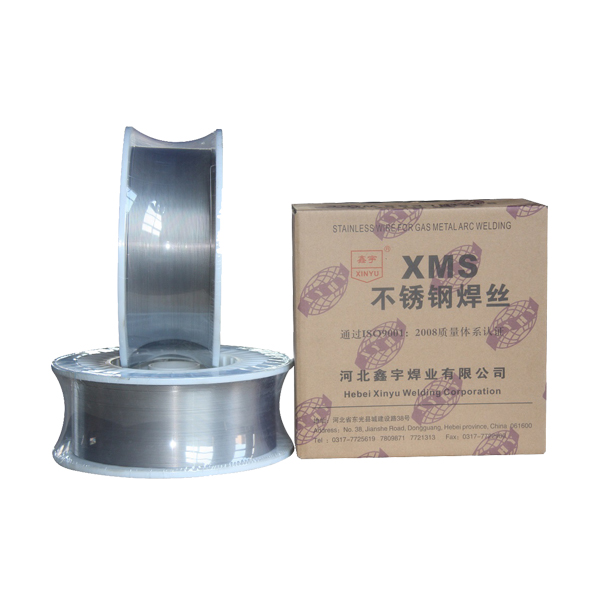

We are stainless steel wire manufacturer in China, and we provide stainless steel wire.